Process Monoflanges

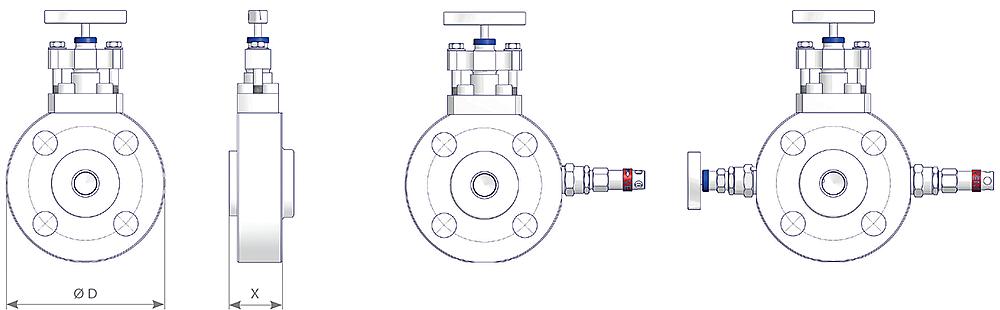

AS-Schneider Process Monoflanges (A frequently used term is also Slimline Monoflange) are designed to replace the traditional primary isolation valve and are close coupled to the process piping flange, for connecting process to instruments. The primary isolation valve needs to be of process design, therefore it's a valve with OS&Y Bolted Bonnet. The secondary isolation valve and the bleed valve are provided with screwed bonnets. The combining of piping and instrument valves into a single unit has benefitted various markets. The Standard Pressure Instrument Connection is 1/2 NPT female, the Standard Process Connections are provided with Flange Connections acc. to ASME B 16.5. AS-Schneider is providing axial, radial or dual outlet types for either Horizontal or Vertical Flange Mounting.

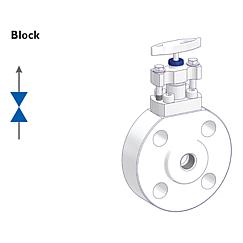

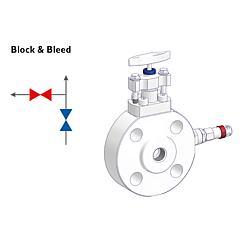

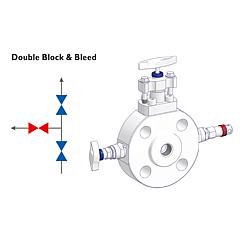

The Monoflanges are available as Block, Block & Bleed or Double Block & Bleed designs.

Connections, materials, valve head unit designs and further options are available, please see below Ordering Information or more detailed under:

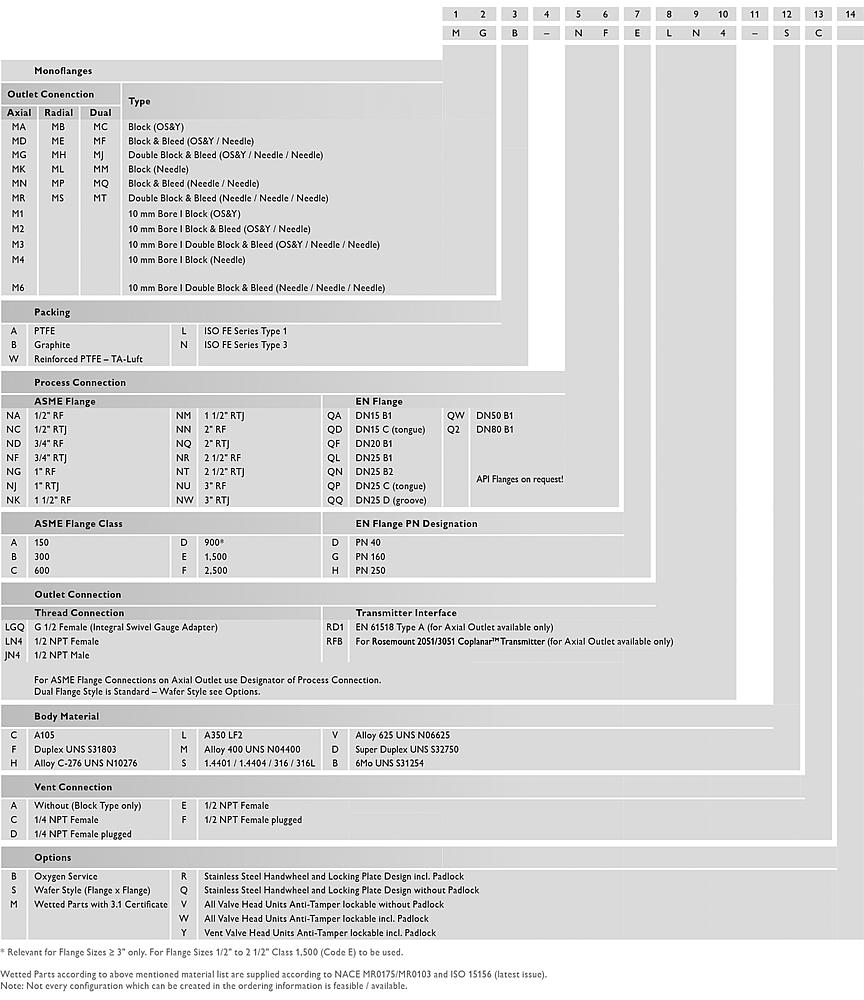

General InformationExample for a typical product acc. to the below mentioned Ordering Information:Part No.: MGB-NNELN4-SC

| MG | Process Monoflange, Double Block & Bleed Type |

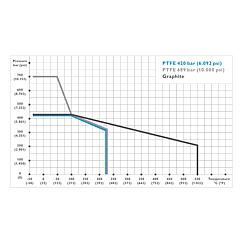

| B | Packing: Graphite |

| - | |

| NN | ASME Flange Size: 2", RF |

| E | ASME Flange Class: 900 / 1.500 |

| LN4 | Outlet Connection: 1/2 NPT Female |

| - | |

| S | Material: 1.4401 / 1.4404 / 316 / 316L |

| C | Vent Connection: 1/4 NPT Female |

Block Block & Bleed Double Block & Bleed

Flange x Thread| Flange Size (in) |

Flange Class | ØD (mm) | Flange Face | Approx. Weight (kg) |

|

| RF x mm | RTJ x mm | ||||

| 1/2 | 150 | 98.6 | 36.6 | - | 2.5 |

| 1/2 | 300 | 98.6 | 36.6 | 40.6 | 2.6 |

| 1/2 | 600 | 98.6 | 41.4 | 40.6 | 2.6 |

| 1/2 | 900 / 1,500 | 120.7 | 41.4 | 41.4 | 3.5 |

| 1/2 | 2,500 | 133.4 | 41.4 | 41.4 | 4.3 |

| 3/4 | 150 | 98.6 | 36.6 | - | 2.6 |

| 3/4 | 300 | 117.3 | 36.6 | 41.4 | 3.5 |

| 3/4 | 600 | 117.3 | 41.4 | 41.4 | 3.5 |

| 3/4 | 900 / 1,500 | 130.0 | 41.4 | 41.4 | 4.1 |

| 3/4 | 2,500 | 139.7 | 41.4 | 41.4 | 4.8 |

| 1 | 150 | 108.0 | 36.6 | 41.4 | 3.0 |

| 1 | 300 | 124.0 | 36.6 | 41.4 | 3.9 |

| 1 | 600 | 124.0 | 41.4 | 41.4 | 3.9 |

| 1 | 900 / 1,500 | 149.3 | 41.4 | 41.4 | 5.1 |

| 1 | 2,500 | 158.8 | 42.4 | 42.4 | 6.1 |

| 1 1/2 | 150 | 127.0 | 36.6 | 41.4 | 4.1 |

| 1 1/2 | 300 | 155.4 | 36.6 | 41.4 | 6.0 |

| 1 1/2 | 600 | 155.4 | 41.4 | 41.4 | 6.0 |

| 1 1/2 | 900 / 1,500 | 177.8 | 41.4 | 41.4 | 7.4 |

| 1 1/2 | 2,500 | 203.2 | 51.4 | 52.9 | 11.4 |

| 2 | 150 | 152.4 | 36.6 | 41.4 | 5.4 |

| 2 | 300 | 165.1 | 36.6 | 42.9 | 6.4 |

| 2 | 600 | 165.1 | 41.4 | 42.9 | 6.9 |

| 2 | 900 / 1,500 | 215.9 | 45.4 | 46.9 | 12.0 |

| 2 | 2,500 | 235.0 | 58.4 | 59.9 | 17.5 |