| Armaturenfabrik Franz Schneider GmbH + Co. KGBahnhofplatz 12 · 74226 Nordheim · Germany Tel. +49 7133 101-0 · Fax +49 7133 101-180 E-mail: contact@as-schneider.com · Internet: www.as-schneider.com |

Nuclear Valves and Manifolds

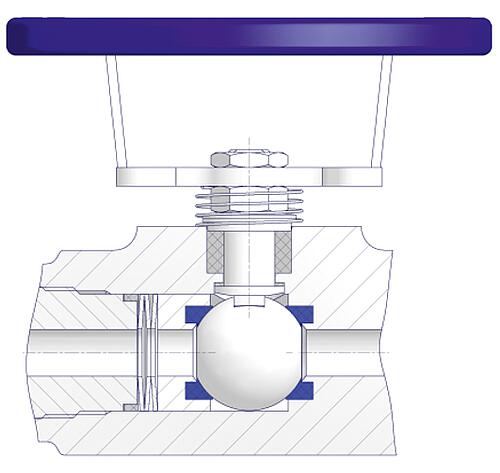

Ball Valve

The K Series Ball Valves are very robust ball valves which are designed especially for severe service for the chemical and petrochemical process industry. End connector and valve body are full penetration welded for environmental protection. Thus enable them perfect for the usage in nuclear services as well.

Features

Optional Features

|

|

Materials

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

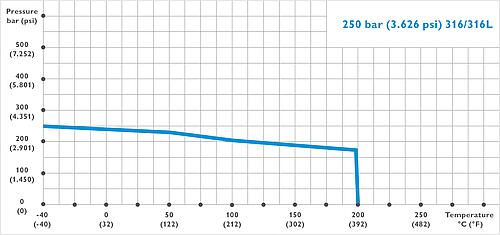

Pressure-Temperature Rating

|