Hydrogen compliant Instrumentation Valves and DBB Piping Ball Valves

For more than 20 years, we have been supporting hydrogen as a medium with our valves. All valves and manifolds as well as our Double Block & Bleed Piping Ball Valves are suitable for up to 100% hydrogen use.

In other words, our instrumentation valves and process valves can also be used safely in natural gas applications with, for example, a 20% hydrogen blending. This feature is of particular interest to natural gas plant operators and gas network operators who want to convert their natural gas pipelines for hydrogen.

Your contact for hydrogen projects

Konrad Nawal

Hydrogen expert at AS-Schneider

You can reach me at

Phone: +49 7133 1010

Email: bdm@as-schneider.com

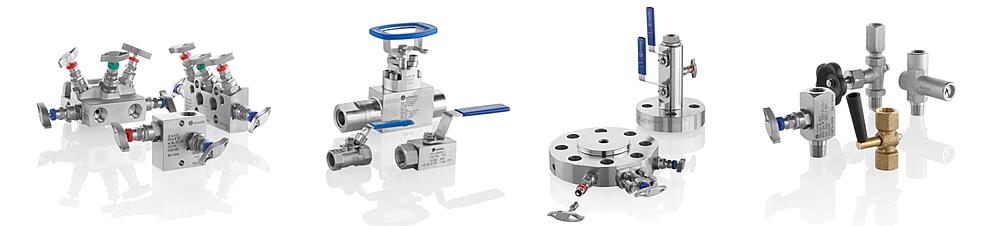

Hydrogen compliant Instrumentation Valves

All our Instrumentation Valves are suitable for up to 100% hydrogen use:

E Series Manifolds, Gauge Valves and Pressure Gauge Accessories, Soft Seated Valves and Manifolds, Schneider DirectMount Systems, Mini Valves, Modular Mounting Systems, Monoflanges & VariAS-Blocks, Needle Type Globe Valves, Ball Valves, F Series Manifolds & Multi-Way Cocks and Flange Adapters.

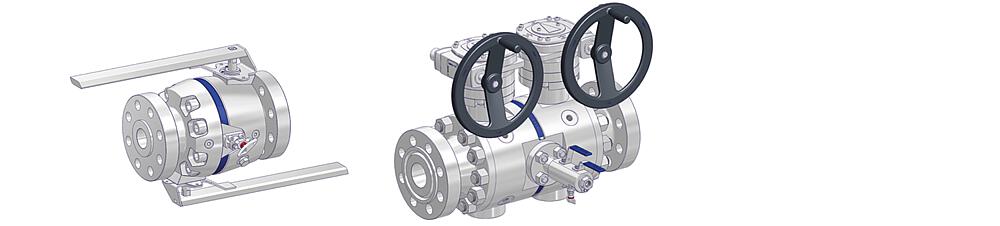

Hydrogen compliant Double Block & Bleed Piping Ball Valves

The 2 Piece Design and 3 Piece Design, Flanged Style of our Double Block & Bleed Piping Ball Valves (Taurus Series) is suitable for up to 100% hydrogen service.

Hydrogen compliant Double Block & Bleed Piping Ball ValvesOther materials are also suitable for hydrogen use. In such a case, we recommend to consult our hydrogen experts personally in order to be able to select the best possible material for your specific requirements.

You should also ensure that non-metallic valve materials such as seals and lubricants are compatible with the hydrogen medium. A list of recommendations can be found in the designated standards and norms (Sandia, ISO / TR, SAE). See also the section on sealing materials below.

Suitable Metallic Materials

| Material | Operating Limits | Recommendation |

| 1.4401 / 1.4404 | -40°C / +538°C |

For hydrogen applications, our experts recommend |

| 316 / 316L | -40°C / +538°C | |

| 1.4571 | -40°C / +538°C | |

Other materials are also available on request.

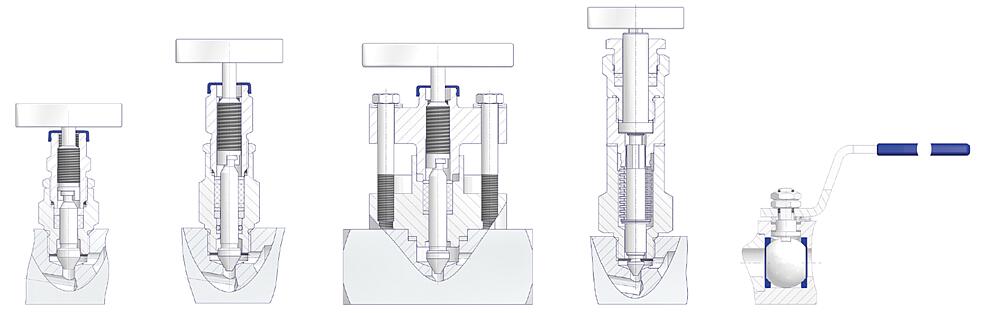

Open Hydrogen Environment (Option W1)

In the case the valve is mounted in an open, ventilated hydrogen application - for example in a forced-ventilated room, or even outdoors, there is no danger of an explosive atmosphere, and the escaping hydrogen is harmless to the environment. For such an application, you can use our standard valve head units.Our Recommendation:

| Valve Head Unit | Sealing System |

| Our Standard Valve Head Unit | PTFE |

Closed Hydrogen Environment (Option W2)

Our Recommendation:

| Valve Head Unit | Sealing System |

| Special Valve Head Unit - Depending on the field of application |

Valve Head Unit tested acc. to ISO 15848-1 (TA-Luft Valve Head Unit) or Bellows Sealed Head Unit |

Suitable Sealing Materials

| Material | Operating Limits | Recommendation |

|

Engineering Plastics |

||

| PTFE | -40°C / +232°C | Recommended by our hydrogen experts. |

| Reinforced PTFE | -40°C / +232°C | |

| PEEK | -40°C / +232°C | |

| Graphite | ||

| Graphite (general) | -200°C / +550°C | |

| O-Rings | ||

| FKM | -60°C / +232°C | Temperature range depending on type. |

| EPDM | -40°C / +120°C | |

| Metallic Bellows | ||

| 1.4571 | -50°C / +538°C | |

Open Hydrogen Environment (Option W1)

In the case of Option W1, the following tests are carried out:

- Acceptance Test Certificate 3.1 for Wetted Parts is provided.

- We ensure that all Metallic Materials and Sealing Materials are suitable for use with Hydrogen.

Closed Hydrogen Environment (Option W2)

In the case of Option W2, the following tests beyond Option W1 are carried out:

- Option W2 restricts the selection to suitable ISO 15848 Part 1 type-tested valve head units or bellows sealed head units.

- Helium testing during series production in accordance with ISO 15848 Part 2 is performed for 10% of the parts.

More valuable information on the topic of hydrogen and its derivatives you can find on our blog page. In our blog, we regularly keep you up to date with technical articles on numerous key topics related to hydrogen as well as power-to-x applications. Browse through the numerous hydrogen blog articles and let us inspire you and expand your knowledge.

So sign up for our newsletter today and make sure you don't miss any new blog articles. Enclosed is an excerpt from the current blog articles on the topic of hydrogen and its derivatives (P2X):

Hydrogen valves and typical application challenges

Modern hydrogen applications demand durable hydrogen valves that operate reliably under high pressure and at extremely low temperatures. Some challenges are facing the industry. In this blog article, we describe relevant key data on hydrogen, hydrogen applications and hydrogen valves.Hydrogen valves and typical applicationWhat are Power-to-X solutions?

Learn in the article what the Power-to-X technologies are by energy form: Power-to-Gas, Power-to-Liquid or Power-to-Heat and why is PtX important for decarbonization.What are Power-to-X solutions?Future importance of Hydrogen & Power-to-X in industrial applications at the EU level

Interview with Dr. Kantz from VDMA on the future importance of hydrogen and Power-to-X (P2X) with a focus on the EU. The topic breaks down into four chapters to reach the core areas of interest with enhanced determination:

( 1 ) Hydrogen in the context of Power-to-X

( 2 ) Legislations for climate protection

( 3 ) Building a hydrogen economy

( 4 ) Involvement of the mechanical & plant engineering sector

Power-to-X for Applications - What is the relevance of this VDMA network?

Read how the VDMA network “Power-to-X for Applications” supports mechanical & plant engineers with the challenges of power-to-X applications.Power-to-X for Applications - What is the relevance of this VDMA network?