Standard Design

Your Benefits

|

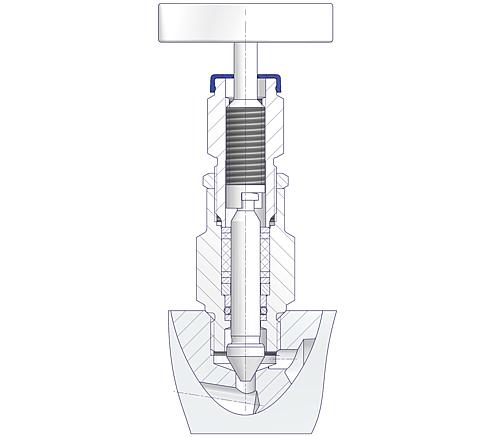

Screwed Bonnet

|

Tightness Class for VariAS-Blocks at Room Temperature (RT) (-29°C to 40°C [-20°F to 104°F])

Double Block & Bleed (Ball / Needle / Ball)

| Ball Seat | Packing Ball Valve | Packing Needle Valve | Tightness Class | ||

| C01 205 Cycles* |

C02 1,500 Cycles |

C03 2,500 Cycles |

|||

| Reinforced PTFE | PTFE | PTFE / Reinforced PTFE | Class A | Class A | Class B |

| Reinforced PTFE | Graphite | Graphite / FKM O-Ring | Class A | Class B | |

| PEEK | PTFE | PTFE / Reinforced PTFE | Class A | Class A | Class B |

| PEEK | Graphite | Graphite / FKM O-Ring | Class A | Class B | |

| Reinforced PTFE | Lip Seal | Graphite / FKM O-Ring | Class A | Class A | Class A |

| PEEK | Lip Seal | Graphite / FKM O-Ring | Class A | Class A | Class A |

| Reinforced PTFE | O-Ring | Graphite / FKM O-Ring | Class A | Class A | Class A |

| PEEK | O-Ring | Graphite / FKM O-Ring | Class A | Class A | Class A |

| Metal Seated | Graphite | Graphite / FKM O-Ring | Class A | Class B | |

* Several Stem Seals meet the requirement of ISO 15848-1, Edition 2006. These are more stringent than these of the current Edition 2015:

– Tightness values are reduced from Edition 2006 to 2015 by the factor of 10.

– Numbers of cycles are reduced from 500 to 205.

Note: The above mentioned table is only valid for Double Block & Bleed Valves (Ball / Needle / Ball). For other types please contact the factory.

Tightness Class for VariAS-Blocks at 200°C (RT to 200°C [-RT to 392°F])

Double Block & Bleed (Ball / Needle / Ball)

| Ball Seat | Packing Ball Valve | Packing Needle Valve | Tightness Class | ||

| C01 205 Cycles* |

C02 1,500 Cycles |

C03 2,500 Cycles |

|||

| Reinforced PTFE | PTFE | PTFE / Reinforced PTFE | Class B | On request | |

| Reinforced PTFE | Graphite | Graphite / FKM O-Ring | Class B | Class B | On request |

| PEEK | PTFE | PTFE / Reinforced PTFE | Class B | On request | |

| PEEK | Graphite | Graphite / FKM O-Ring | Class B | Class B | On request |

| Reinforced PTFE | Lip Seal | Graphite / FKM O-Ring | Class B | On request | |

| PEEK | Lip Seal | Graphite / FKM O-Ring | Class B | On request | |

| Reinforced PTFE | O-Ring | Graphite / FKM O-Ring | Class B | On request | |

| PEEK | O-Ring | Graphite / FKM O-Ring | Class B | On request | |

| Metal Seated | Graphite | Graphite / FKM O-Ring | Class B | Class B | On request |

* Several Stem Seals meet the requirement of ISO 15848-1, Edition 2006. These are more stringent than these of the current Edition 2015:

– Tightness values are reduced from Edition 2006 to 2015 by the factor of 10.

– Numbers of cycles are reduced from 500 to 205.

Note: The above mentioned table is only valid for Double Block & Bleed Valves (Ball / Needle / Ball). For other types please contact the factory.