Instrumentation Valves and DBB Valves for use with Fugitive Emissions

At AS-Schneider, we have been experts in the effective control of Fugitive Emissions from valves for more than a decade.

Our Instrumentation Valves and Process Valves are available acc. to ISO 15848-1 and the TA-Luft option acc. to the amendment (status 2021). Our extensive portfolio has been certified by TÜV Süd.

In 2011, we already received the first ISO 15848-1 certificate and have thus basically met the requirements of the new TA-Luft for more than 10 years.

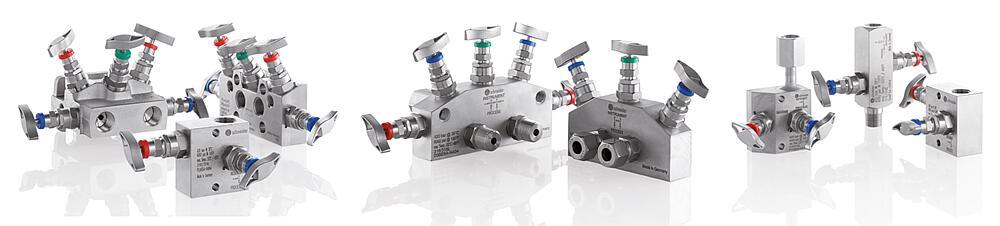

E Series Manifolds for use with Fugitive Emissions

E Series Manifolds for use with Fugitive Emissions

Monoflanges for use with Fugitive Emissions

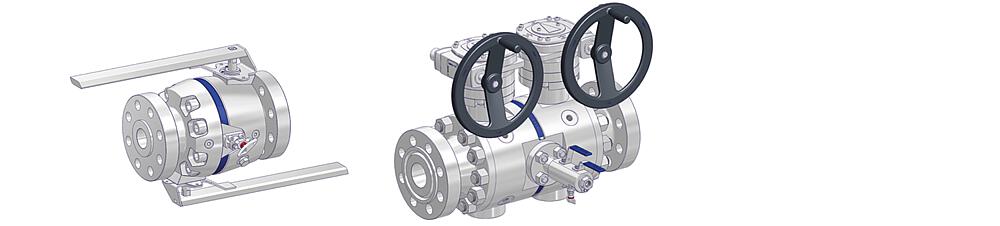

Monoflanges for Use with Fugitive EmissionsVariAS-Blocks and Ball Valves for use with Fugitive Emissions

VariAS-Blocks Products for use with Fugitive EmissionsBall Valves for use with Fugitive Emissions

Double Block & Bleed Piping Ball Valves for use with Fugitive Emissions

DBB Piping Ball Valves for use with Fugitive EmissionsEnclosed you will find an overview of our Valve Head Units for use with Fugitive Emissions:

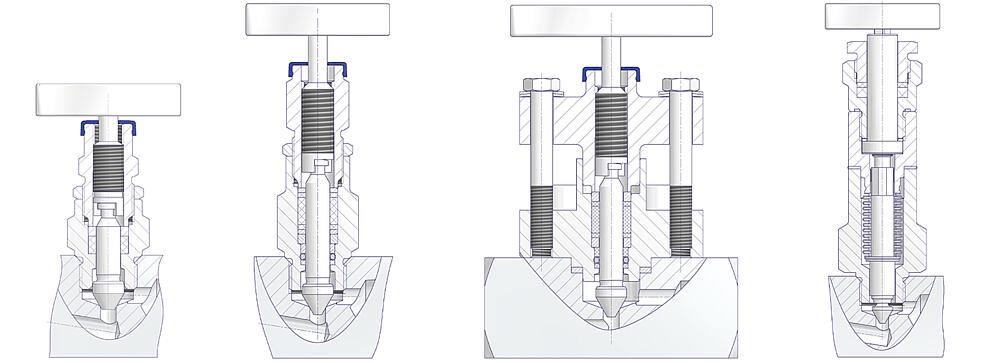

Standard- Needle Valve OS&Y Needle Valve Bellows Sealed

Valve Head Unit ISO FE Type 1&3 Head Unit

ISO FE Type 4&5

AS-Schneider offers a variety of ISO 15848-1 solutions that comply with the new TA-Luft 2021. Since the tightness class is defined in the TA-Luft, this cannot be selected.

However, in order to find the optimal solution, the following must be considered:

( 1 ) Chemical resistance

Check possible restrictions regarding the seal material (PTFE, Graphite, FKM Elastomer, Bellows). It is important to ensure that the selected seal material meets the specific requirements of your application.( 2 ) Endurance class

TA-Luft does not give any specific information on the endurance class, but it requires that testing and maintenance of sealing systems must be specified in management instructions in order to ensure leak-tightness in the long term. To save this effort, AS-Schneider valves are designed to be maintenance-free under certain conditions.For example, instrumentation valves with strength class CO1 (205 mechanical cycles) can be considered maintenance-free over a period of 30 years if they are operated no more than 7 times per year (205 cycles / 30 years = 6.8 cycles per year).

If a higher frequency of operation is required, a solution with a higher strength class should be selected.

( 3 ) Pressure and temperature

Make sure that the certified pressure and temperature range of the valves is sufficient for your specific application. It is essential that the valves can withstand the operating conditions to ensure reliable and safe operation.| AS-Schneider Type | Sealing Material | Max. Pressure | Temperature Range | Endurance Class / Mechanical Cycles |

|

Screwed-in Valve Head Units |

||||

| E Series | PTFE | 420 bar (6.092 psi) | -29°C to +82°C (-20°F / +180°F) |

C01 / 205 |

| 207 bar (3.000 psi) test medium methane |

-29°C to +93°C (-20°F / +200°F) |

C02 / 1,500 | ||

| E Series | Graphite | 420 bar (6.092 psi) | -29°C to +82°C (-20°F / +180°F) |

C01 / 205 |

| ISO FE Type 4 | Graphite Packing | 420 bar (6.092 psi) | -50°C to +400°C (-58°F / +200°F) |

CO1 / 205 |

| ISO FE Typ 5 | Carbon filled PTFE | 420 bar (6.092 psi) | -50°C bis +200°C (-58°F / +392°F) |

CO1 / 205 |

|

OS&Y Valve Head Units |

||||

| ISO FE Type 4 (OS&Y) | Graphite Packing | 420 bar (6.092 psi) | -50°C to +400°C (-58°F / +200°F) |

CO1 / 205 |

| ISO FE Typ 5 (OS&Y) | Carbon filled PTFE | 420 bar (6.092 psi) | -50°C bis +200°C (-58°F / +392°F) |

CO1 / 205 |

|

Bellows Sealed Valve Head Units |

||||

| Bellows | Metallic Bellows with Safety Stuffing Box. |

250 bar (3.626 psi) | Meets the requirements of the TA-Luft without proof. |

|

|

Ball Valves |

||||

| KB1-, KB3-, KC1-, KC3- with XCE-Sealing System |

Carbon filled PTFE | 420 bar (6.092 psi) | -29°C to +40°C (-20°F / +104°F) |

CO1 / 205 |

|

KB2-, KB4-, KC2-, KC3- |

Primary Seal: Carbon filled PTFE and Graphite Packing |

420 bar (6.092 psi) | -29°C to +40°C (-20°F / +104°F) |

C01 / 205 |

|

VariAS-Blocks |

||||

|

VariAS-Block with |

Primary Seal: |

420 bar (6.092 psi) | -29°C to +200°C (-20°F / +392°F) |

CO1 / 205 |

|

VariAS-Block with |

Primary Seal: |

420 bar (6.092 psi) | -29°C to +200°C (-20°F / +392°F) |

C01 / 205 |

Detailed information on the subject of TA-Luft and the TA-Luft amendment (2021) can be found on our blog page. In our blog, we regularly keep you up to date with technical articles on numerous key topics relating to TA-Luft and TA-Luft applications. Browse through the numerous TA-Luft blog articles and enjoy being inspired and expanding your knowledge.

Our recommendation to you: Sign up for the newsletter oday so that you will no longer miss any new blog articles. Enclosed is an excerpt from the current blog articles on the topic of TA-Luft and the TA-Luft amendment (2021):

The revised TA-Luft Emission Standard refers to ISO 15848-1 to protect the general public and the neighborhood. And to prevent harmful effects on the environment caused by air pollution. All that in order to achieve a high level of protection for the environment as a whole. In our blog article, we explain what impact this change will have on the valve industry.

Impact of revision of the TA-Luft on the valve industry