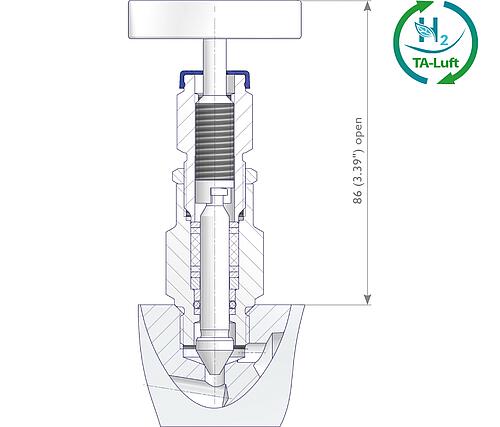

Screwed Bonnet

|

|

ISO FE – Performance Data

ISO FE Type 1:

Class A 1,500 cycles / –29°C to 40°C (–20°F to 104°F)

Class A 205 cycles / –29°C to 200°C (–20°F to 392°F)

Class B 1,500 cycles / –29°C to 200°C (–20°F to 392°F)

ISO FE Type 3:

Class B 1,500 cycles / –29°C to 200°C (-20°F to 392°F)

ISO FE Type 4:

Class A 1,500 cycles / –50°C to 400°C (–58°F to 752°F)

ISO FE Type 5:

Class A 205 cycles / –50°C to 200°C (–58°F to 392°F)

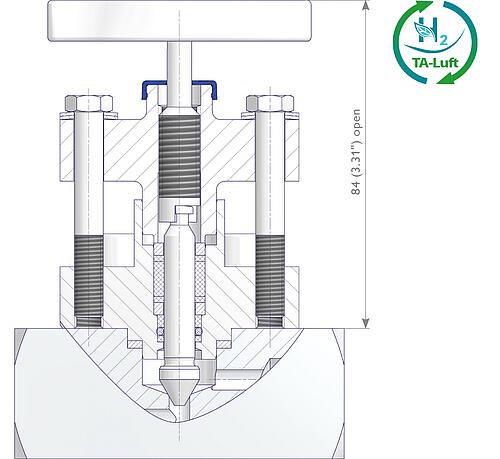

QS&Y Bolted Bonnet

|

|

ISO FE – Performance Data

ISO FE Type 1:

Class A 2,500 cycles / –29°C to 40°C (–20°F to 104°F)

Class A 500 cycles / –29°C to 200°C (–20°F to 392°F)

Class B 2,500 cycles / –29°C to 200°C (–20°F to 392°F)

ISO FE Type 3:

Class B 2,500 cycles / –29°C to 200°C (–20°F to 392°F)

ISO FE Type 4:

Class 205 cycles / –50°C to 400°C (–58°F to 752°F)

ISO FE Type 5:

Class 205 cycles / –50°C to 200°C (–58°F to 392°F)

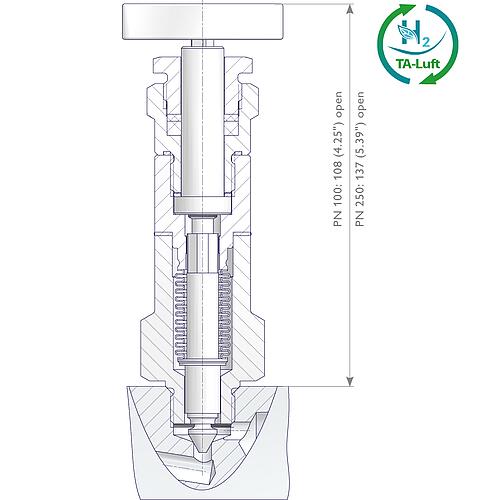

Screwed Bonnet – PN 100 and Graphite Safety Packing PN 250 and Graphite Safety Packing Features

Bellows Sealed Head Units are mainly used for applications requiring the highest tightness class – such as toxic or vacuum service. |

|

|

Attention: |