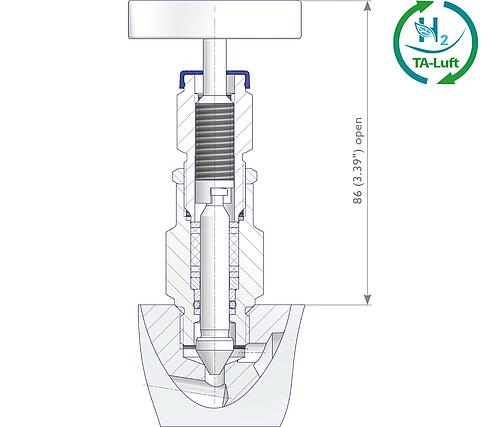

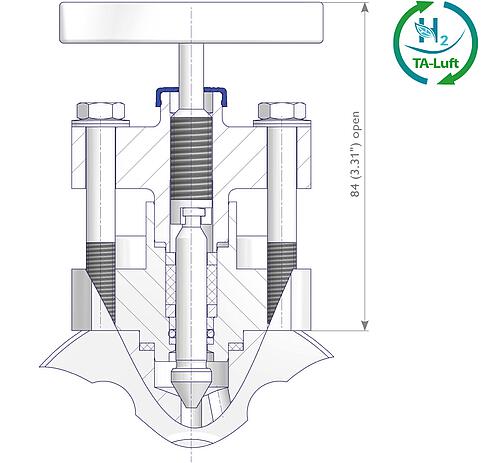

QS&Y Bolted Bonnet

– Type 1 O-Ring Needle Seal + Graphite Packing

Type 3 PTFE Packing

Features

- Integral Valve Seat – Metal to Metal Seated

- Non-rotating Needle

- External Stem Thread – Packing below stem threads.

Stem Threads are protected from process media (non-wetted).

- Stem with cold rolled threads

- Blow-out proof Needle

- Spring Washers for compensation of thermal expansion

- Back Seat – Metal to metal secondary stem seal

- Color Coded Dust Cap for operating thread protection

- Needle Seal: Standard Packing in PTFE or Graphite plus FKM O-Ring Needle Seal - RGD resistant

- Bonnet Seal Ring: Graphite

- Fire Safe approved acc. to ISO 10497 and API 607; Graphite Packing only

- Max. allowable (Working) Pressure (PS): 420 bar (6,092 psi)

- Anti-Tamper Valve Head Options available

- All Non-wetted Parts in 316 Stainless Steel

- Types also comply with the requirements of TA-Luft 2021

ISO FE Performance Data

ISO FE Type 1:

Class A 2,500 cycles / –29°C to 40°C

(–20°F to 104°F)

Class A 500 cycles / –29°C to 200°C

(–20°F to 392°F)

Class B 2,500 cycles / –29°C to 200°C

(–20°F to 392°F)

ISO FE Type 3:

Class B 2,500 cycles / –29°C to 200°C

(–20°F to 392°F)