Gauge Valves and Pressure Gauge Accessories

General Features

Gauge Protectors I Features and Benefits

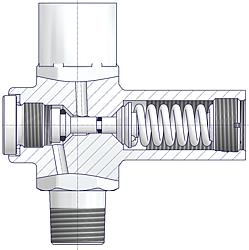

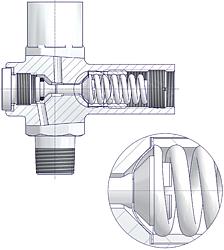

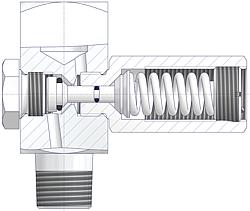

AS-Schneider Gauge Protectors are used to protect pressure-sensing instruments against damage, loss of accuracy, and/or rupture in the event of excessive system pressure. The piston assembly works against an adjustable spring. The piston assembly contains a sealing mechanism to isolate system pressure from the instrument.

The Inlet to Outlet seal is an O-Ring, the sealing to atmosphere is realized by either another O-Ring (system pressures of more than 2 bar) or a diaphragm (for system pressures 0.4 up to 2.5 bar). As system pressure overcomes the force of the spring, the piston moves, causing the sealing system to close. The outlet side is now isolated from increasing system pressure and the instrument is protected. As system pressure drops to the reopening pressure (25% below the closing pressure), the valve opens again.

The Inlet to Outlet seal is an O-Ring, the sealing to atmosphere is realized by either another O-Ring (system pressures of more than 2 bar) or a diaphragm (for system pressures 0.4 up to 2.5 bar). As system pressure overcomes the force of the spring, the piston moves, causing the sealing system to close. The outlet side is now isolated from increasing system pressure and the instrument is protected. As system pressure drops to the reopening pressure (25% below the closing pressure), the valve opens again.

Standard Features

The Gauge Protectors are as a standard available for sour gas service in accordance with NACE MR0175/MR0103 and ISO 15156 except the Brass Type. Pressure Test: A shell test and a seat test are performed at 1.5 times the maximum working pressure acc. to EN 12266-1 - P10, P11 and P12. The closing pressure is normally adjusted to the average value of the relevant adjusting range – For example adjusting range 2-6 bar = 4 bar closing pressure. |

Optional Features

DVGW approved Gauge Protectors:

|

| Components | Brass | Stainless Steel | Duplex | Alloy 400 | Alloy C-276 | Alloy 625 |

| Material / Material No. | ||||||

| Body | Brass | 1.4571 | 316 * | Duplex | Alloy 400 | Alloy C-276 | Alloy 625 |

| Bonnet | 316 * | Duplex | Alloy 400 | Alloy C-276 | Alloy 625 | |

| Piston | 1.4404 * | 1.4404 * | 316 * | Duplex | Alloy 400 | Alloy C-276 | Alloy 625 |

| Piston Seals | FKM (FPM by ISO) | |||||

| Screw Plug | 1.4404 * | 1.4404 * | Duplex | Alloy 400 | Alloy C-276 | Alloy 625 |

| Adjusting Screw | 1.4404 * | |||||

| Spring | Stainless Steel | |||||

| Adjusting Nut | Unalloyed Steel | Stainless Steel | ||||

* 316 / 316L / 1.4401 / 1.4404

Gauge Protector Type S005.50